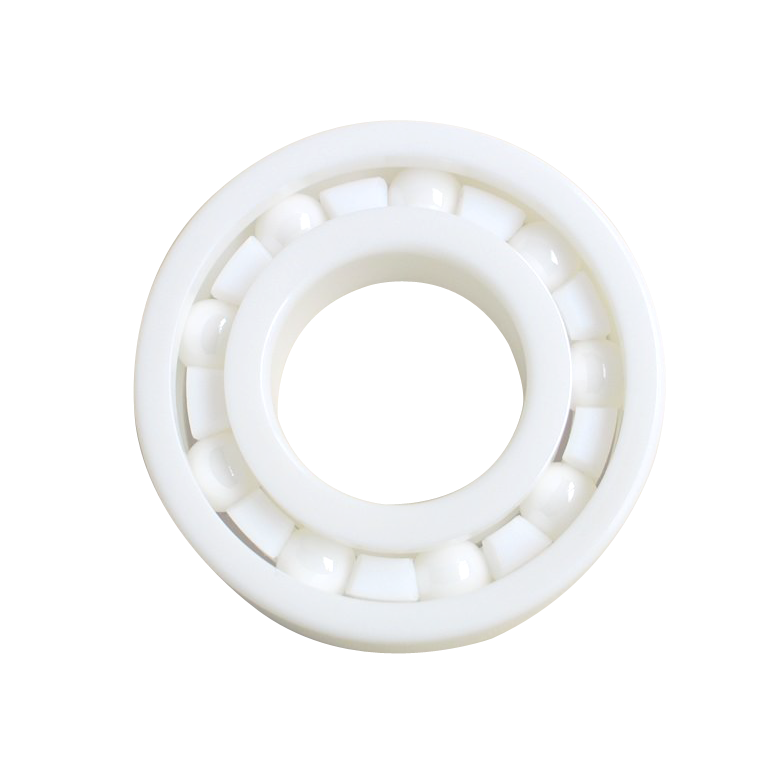

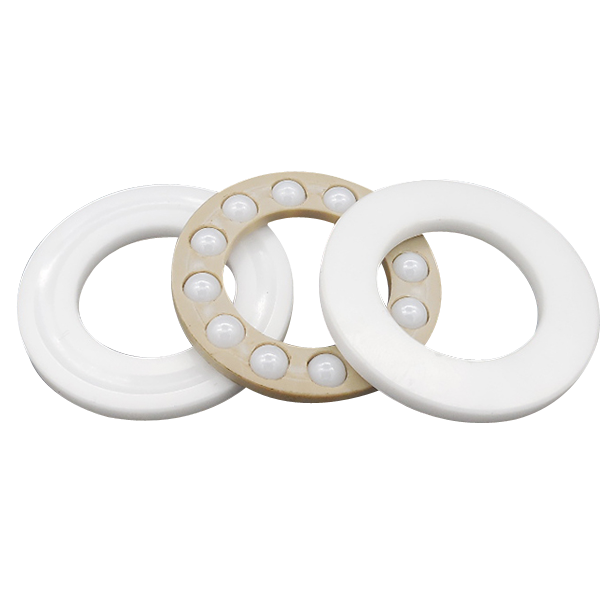

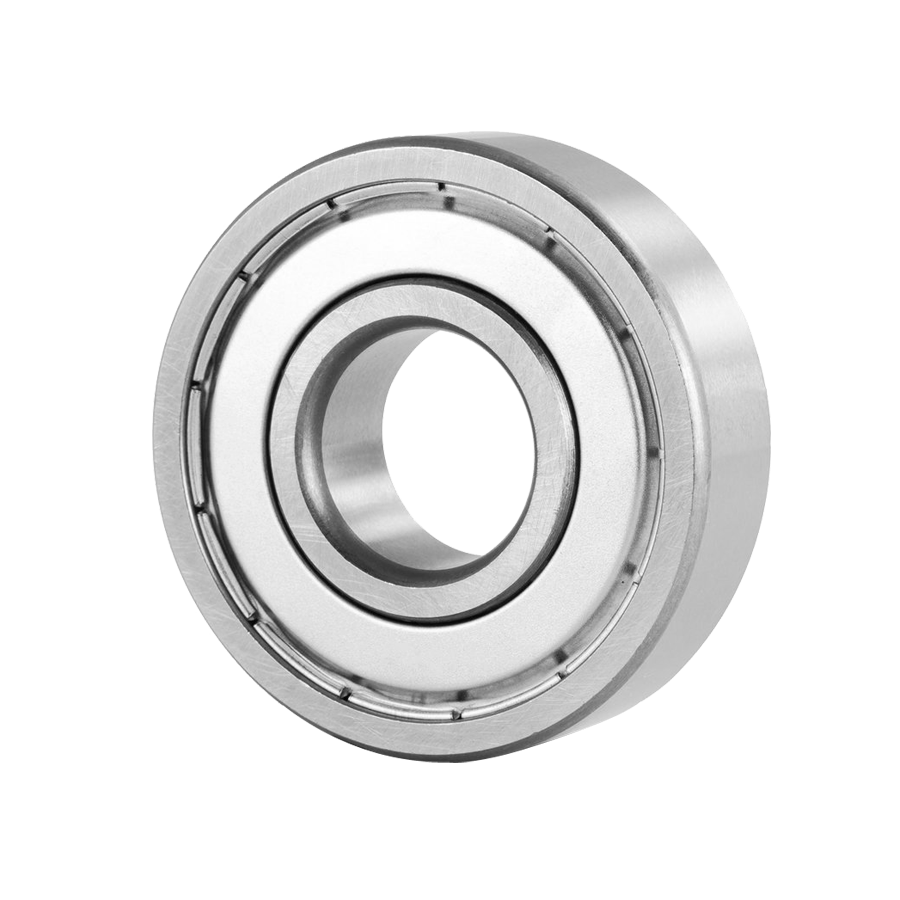

Hybrid bearings have many advantages that set them apart from conventional steel bearings; however, there is also a disadvantage or two. We’ll start with the advantages.

Advantages:Increased Speed Capabilities

Silicon nitride is 58% less dense than conventional bearing steel which minimizes the centrifugal forces acting on the raceway as the ceramic balls rotate. This increases the speed capabilities by 20-50%.

Applications: Motorsport, Machine Tool Spindles, Turbomachinery and Dental Drills.

Increased Lifetime

Silicon nitride is roughly 2 times harder than standard bearing steel. This causes the ceramic balls to polish the metallic raceway as it rotates creating a smoother running surface thus prolonging lifetime.

Applications: any application trying to maximize service life.

Spanisch

Spanisch Französisch

Französisch Deutsche

Deutsche Tschechisch

Tschechisch Portugal

Portugal Italien

Italien Koreanisch

Koreanisch japanisch

japanisch Vietnamesisch

Vietnamesisch Türkisch

Türkisch Arabisch

Arabisch Russisch

Russisch Tschechisch

Tschechisch Thai

Thai irisch

irisch bulgarisch

bulgarisch Polen

Polen kroatisch

kroatisch ukrainisch

ukrainisch bosnisch

bosnisch litauisch

litauisch lettisch

lettisch rumänisch

rumänisch griechisch

griechisch dänisch

dänisch Ungarn

Ungarn norwegisch

norwegisch finnisch

finnisch Niederländisch

Niederländisch Schwedisch

Schwedisch slowakisch

slowakisch Slowenisch

Slowenisch Indonesisch

Indonesisch Bengali

Bengali serbisch

serbisch Usbekisch

Usbekisch